Contact Us

- Tel:

86-532-86552119

- E-mail:

decho@dechometalworks.com

- Address:

Feicheng High-tech development zone, Tai'an City, Shandong Province

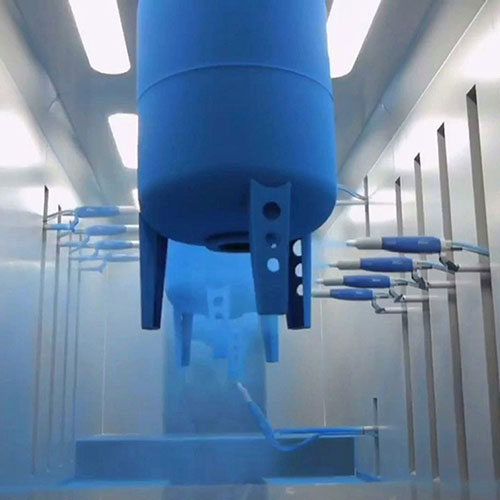

Electrostatic Powder Coating

The working principle of electrostatic powder spraying method is almost identical to that of general liquid coatings, except that powder spraying is dispersed rather than atomized. It is a coating sprayed by an electrostatic powder spray gun, which disperses and causes the powder particles to carry negative charges. The charged powder particles are coated onto the grounded coating by the action of airflow (or centrifugal force or other forces) and electrostatic attraction, and then heated, melted, and solidified into a film. Electrostatic powder spraying method is the dominant powder coating method in the industrial coating field

Electrostatic spraying can be divided into powder spraying and fluorocarbon spraying. The raw materials for powder spraying are polyurethane, polyurethane resin, epoxy resin, hydroxyl polyester resin, and epoxy/polyester resin, which can be prepared in various colors. The characteristics of powder spraying: The spraying equipment is manual, with automatic hanging type, simple construction, coating thickness of over 30 microns, good impact resistance, wear resistance, corrosion resistance, weather resistance, etc. The coating price is cheaper than fluorocarbon. The biggest weakness of powder spraying is the fear of ultraviolet radiation from the sun. Long term exposure can cause natural fading, and the color difference between the sunny and non sunny surfaces of aluminum plates is obvious after a few years, usually within 2-5 years. Now there is a name called colored aluminum profile on the market, which is used for aluminum doors and windows, and is sprayed with ordinary aluminum profile powder. Increase the variety of colors for aluminum doors and windows, while also enhancing their corrosion resistance.

Another type of electrostatic spraying is liquid spraying, also known as fluorocarbon spraying, and in Hong Kong it is called curium oil. Belonging to high-end spraying, the price is relatively high and has long been applied abroad. In the past two years, aluminum curtain walls have only been widely used in China, and due to their excellent characteristics, they are increasingly valued and favored by the construction industry and users. Fluorocarbon spraying has excellent color fading resistance, frost resistance, corrosion resistance to atmospheric pollution (acid rain, etc.), strong UV resistance, strong crack resistance, and ability to withstand harsh weather environments. It is beyond the reach of ordinary coatings.